FAA PART 21 PMA MANUFACTURING

Rotorcraft Services Group Products

RSG Products is a FAA Part 21 PMA approved manufacturing organization that provides products and manufacturing services to the aerospace community. In addition to being the established leading manufacturer of lightweight, high-performance Air-Conditioning Solutions. RSG Products proudly offers Blower Motors, CNC Aerospace Machining, UV Laser Wire Marking, Custom Fabrication, Specialty Manufacturing, Standard Finishing, and Custom Kitting.

In addition to being a leading manufacturer of lightweight, high-performance air-conditioning solutions it offers blower motors, EMS Solutions, CNC Aerospace Machining, UV Laser Wire Marking, Custom fabrication, Standard Finishing, and Custom Kitting.

RSG Products is a Part 21 FAA Parts Manufacturer

- ISO 9001:2016 and AS9100D

- Approved Manufacturer and Exporter under ITAR license # M26241

- Parts Manufacturer Approval under PMA # PQ03883SW

- Special Kit Production

- Proprietary Air Conditioner and Video Products.

- Garmin G500H Bracket Kits & Instrument Panels.

- Production of “STC’d” Auto Pilot Kits for Sagem Avionics.

- Machine shop.

Approved Supplier For:

High Performance Air Conditioning

RSG Products modifies, manufactures, and distributes the finest quality air conditioning and video systems for a wide range of helicopter models.

Every RSG product is manufactured with pride in the USA with OEM and FAA PMA approval in our 25,000 sq. ft. Saginaw, TX facility, and fully inspected prior to delivery by a team of experienced and qualified inspectors to ensure exacting performance and reliability.

RSG air conditioners are easy to install, simple to use, and designed to decrease maintenance time and expense. RSG air conditioning systems are the lightest weight and most reliable in the industry. These systems are currently installed in aircraft world-wide and AOG parts support is provided to every customer.

| FAA STC / PMA APPROVED AIR CONDITIONING SYSTEMS | |

| SR00060DE | Agusta A109 Series Air Conditioning System |

| SH3509SW | Airbus AS350/EC130B4 Air Conditioning System |

| SH5947SW | Airbus AS355 Series Air Conditioning System |

| SH5632SW | Airbus AS365 Series Air Conditioning System |

| SR09251RC | MD Helicopter 369 Series Air Conditioning System |

| SR09251RC | MD Helicopter 500 Series Air Conditioning System |

- FAA STC approved PMA kits.

- Lightweight modular and energy efficient design.

- Engineered for reliability and ease of maintenance.

- High capacity/high flow in compact design.

- Detailed installation and maintenance instructions manuals.

- Installation technicians available for training & support worldwide.

- Best in industry warranty support.

- Multiple configuration options to suit every need.

Blower Motor Manufacturing

To provide FAA PMA high quality blower assemblies for use on helicopters, RSG dedicates time and resources to the design, certification, and manufacture it’s own blower motors. This ensures we continue to provide quality products with short lead times and prevent obsolescence.

We provide 5” and 7” brushless blower motors for evaporator and condenser assemblies. All of our air conditioning systems utilize the brushless blower motors and any existing systems can be retrofitted from the brushed style motors to decrease replacement part cost and maintenance time.

Call Now To Order:

+1.817.624.6600

5-Inch DC Brushless Blower Assembly

IFSS 050143-2 DCB, REV A

Two Speed, Has Insulation with Foil Covering, two Ferrites & Heat Shrink. For use on the aft evaporator on H125 (AS350) and dual evaporators on H130 (EC130 B4) models.

7-Inch DC Brushless Blower Assembly

Commitment to Quality

RSG is committed to superior production through its highly regulated quality control process, experienced personnel, and contemporary inspection equipment.

Certifications

- FAA PMA Part 21 Certified

- AS9100 Certified

- ISO 9001 Certified

No matter if you need a single part or small-batch production runs, each part produced by RSG Products is subject to the same regimented inspection process to ensure precision manufacturing and part performance is met.

EMS

When seconds count, count on RSG to provide a safe and secure environment for EMS operators.

RSG has been providing modification, retrofit, completion services and component overhaul to the air medical industry for almost 50 years.

Attending to patient’s needs can be a demanding and critical situation in an airborne environment. RSG understands these needs and takes pride in every completion. An RSG customization combines your medical expertise with our aeronautical ingenuity. Utilizing dependable equipment that can be installed and removed quickly and keeping patients and EMS operators safe and secure while in transit is our top priority!

Other STC Options

EMS Interior Packages

Airbus AS 365/AS 565 Air Medical Services (EMS) Interior

Patient Loading Systems

RSG-135-145-PLS-Options.pdf

Medical Utility Flooring

RSG-145-Medical-Floor-Install.pdf

Litter Systems

AS350/355, SA365 Dual Pivoting Litter Options

Bell 412EP Six Place Litter System

Fixed/Swivel/Tracking Attendant Seats

EC 135/145 Medical Attendant Seating Options

AS350/355 Fold-up Attendant Seating Options

- Modular Emergency Medical System (MEMS)

- Equipment Panel

- Respiratory Oxygen System

- I.V. Track Assembly

- Propaq Mounts

- Zoll Defibrillator Mount

- Electrical Support Package

- Soft Pocket Storage

- Blackout Curtain

- Hoist Mount for Goodrich 600 Lbs Rescue Hoist

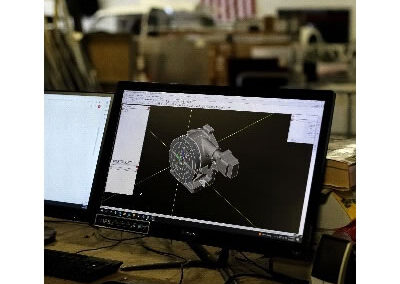

CNC Aerospace Machining Services

RSG Products proudly offers its outstanding manufacturing services to support the needs of other manufacturers including:

- Exceeding the standard for inceptive production and parts manufacturing.

- Low volume manufacturing requirements.

- Short-run parts and prototyping simple to complex parts for aerospace applications.

- Development of basic parts requiring high tolerances, custom tooling, and even creative machining.

- Production substrates include aluminum, stainless steel, dense foam, plastics, and brass.

- Programming/CAD/CAM Services.

- PMA Approval for STC Holders.

- Assembly & Kitting.

- Robust ERP System.

| CNC AEROSPACE MACHINERY AND USES | ||

| Machine | Span | Primary Use |

| ATRUMP AL42 Vertical Machining Center | X AXIS = 41.3, Y AXIS = 23.6, Z AXIS = 24.0 | 3 axis, 4TH AXIS Rotary, of all types of partsteel & aluminum |

| Birmingham B3VS Vertical Machining Center | X AXIS= 41.0, Y AXIS = 20., Z AXIS = 23.0 | 3 Axis CNC of all types of steel &aluminum parts |

| Sharp TMV Vertical Conventional Milling Machine | X = 39., Y = 16.3, Z = 15.3, Quill = 5.0 | Gen Milling, Drilling, Slotting, Other |

| VMTCNC CNC210 Lathe-Swing OB | Swing OB =210mm, x = 90mm, Z =300mm, 4 Pos Tool Changer | Smaller, high part count jobs. AluminumPlastics, Brass, Other |

| Clark 14 x 40 Conventional Lathe | Swing 14”, Spindle Hole 1-1/2” Dia., DRO,etc. | Turning, Threading, Boring, Grooving,Other, All Materials | Support Items: Plasma Cutter, Acetylene Cutting , Welding, Shop Saws, and more |

CNC Milling

Part Examples

- SolidWorks

- Esprit CAM

- AutoCad

- Autodesk Inventor